Robotics is no longer just about speed or force: today it means integration, precision and adaptability. At Dema we develop robotic systems that not only replace human work, but enhance it, making every production process safer, more scalable and competitive.

Every company has its own flow, every line its own complexities. Our strength is to translate them into industrial solutions that work 24/7 with no margin for error. Not standard replicas, but solutions tailored to the process: from food to medical, from automotive to micro-processing.

With this approach, DEMA takes its industrial automation expertise beyond the electric motor sector, offering tailor-made solutions for welding, quality control, assembly and packaging.

Over the years we have faced very different challenges, testing our method in transversal contexts:

The examples shown are just a few stages of a know-how that embraces our entire core business, with applications of industrial robotics in very different areas.

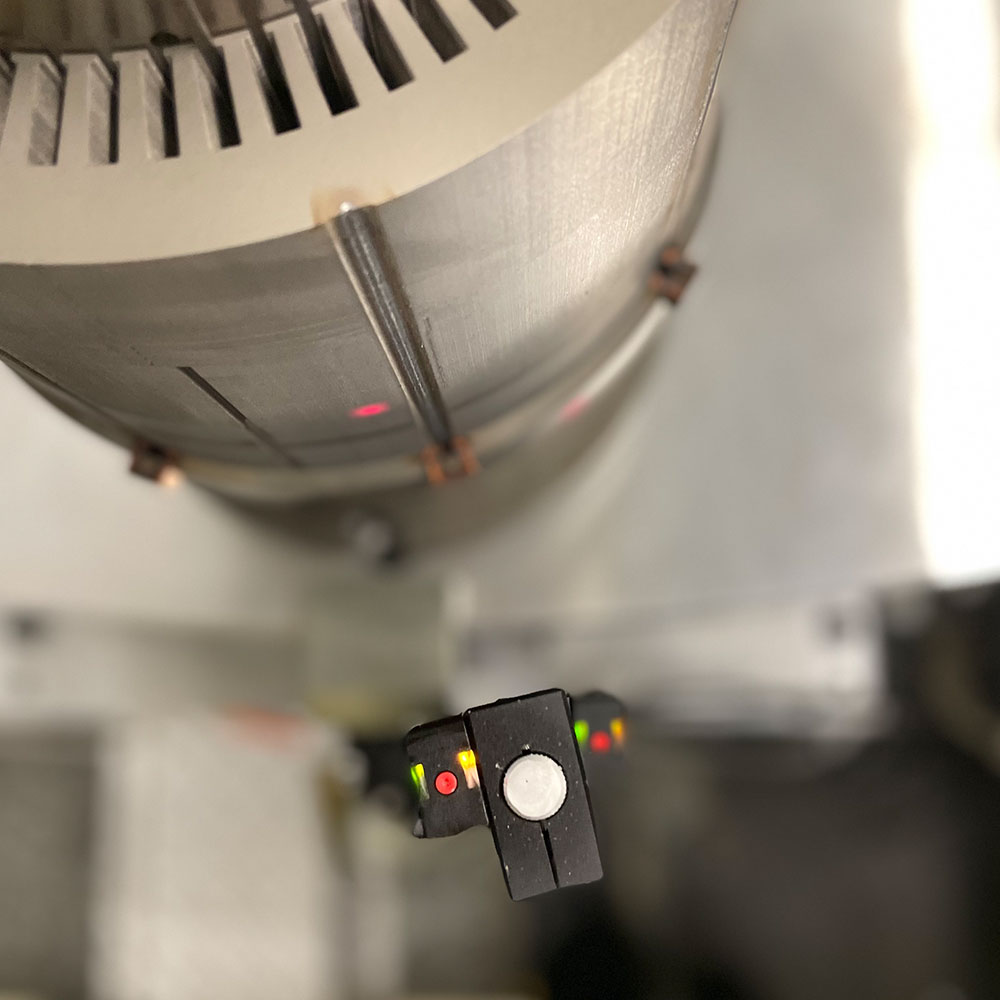

Among the most innovative experiences, Siemens has chosen DEMA as a partner for the design and mechanical construction of a new generation machine: the Smart Digital Inspection System.

Not a technological showcase, but a real machine, designed to concretely develop and test new digital applications — from AI to digital twins, up to advanced vision.

For DEMA, it is a strategic project: it allows us to experiment in advance with the most advanced technologies and immediately transfer their benefits to the machines we build every day for our customers.

A concrete way to stay one step ahead.

Very different experiences, but with one thing in common: the ability to automate complex activities, transforming them into fast, precise and repeatable processes.

In each system you will find our method: listening, careful design, clean execution and direct interface with those who really work on the machines.

Our goal is one: to simplify complexity and transform it into operational efficiency.

Whether it’s automating a single step or an entire process, we accompany you every step of the way, with flexible and scalable solutions.

Do you have a specific idea or need? Let’s translate it into concrete automation together.

Intelligent automation, solutions without boundaries

It’s not just robotics: it’s the competitive advantage that makes your processes faster, safer and more sustainable.

With Dema’s robotics, we integrate artificial intelligence, advanced vision and digital technologies to create tailor-made solutions dedicated to the most strategic phases of production: assembly, welding, control and packaging.

Learn how to turn complexity into operational efficiency, in every industry.

Precision that makes the difference

Our automated welding systems – laser, plasma, TIG and MIG – guarantee maximum repeatability, total process control and consistent quality, regardless of the component geometry.

Key points:

From the choice of technology to the fine-tuning of the parameters, up to the obtaining of the welded joint: with DEMA you have a partner who supports you at every stage.

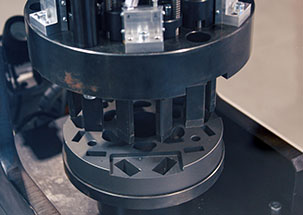

Real-time control, zero defects

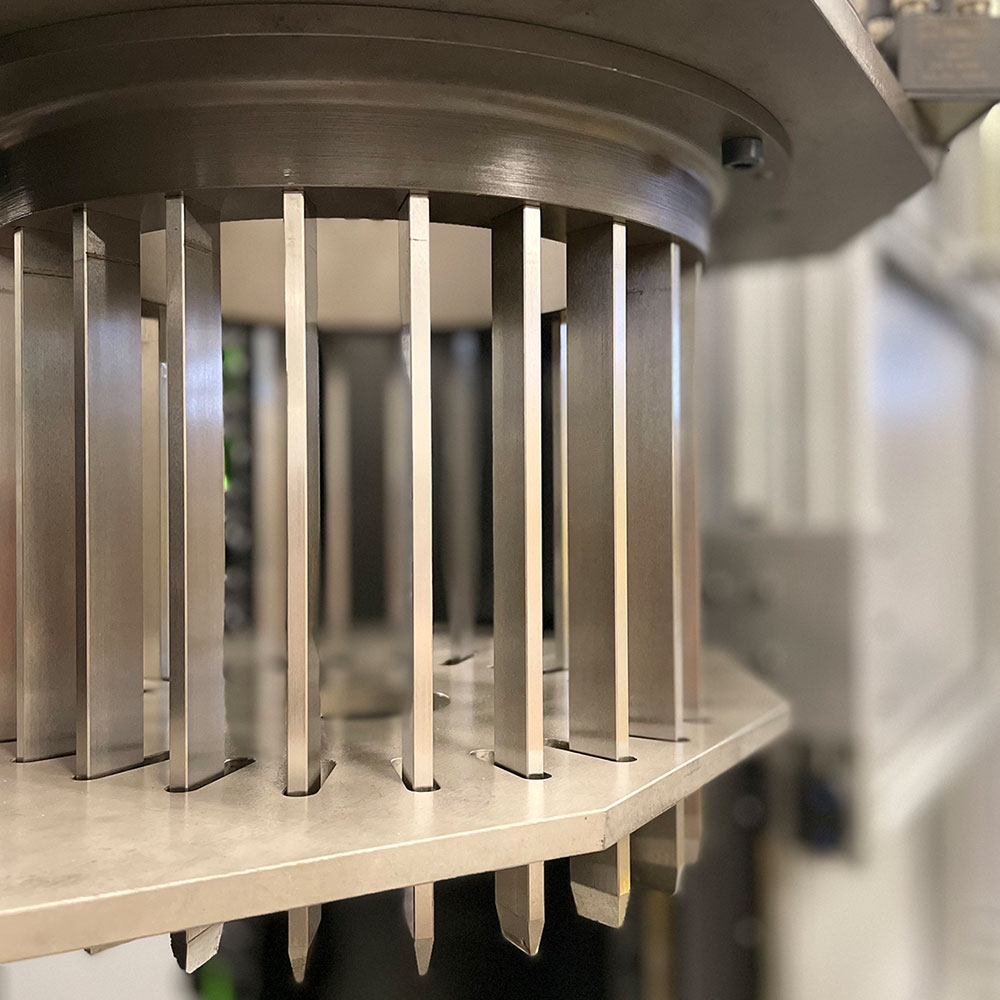

Our inspection systems combine machine vision, advanced sensors and mechanical controls, and each station is designed to automatically verify all critical product parameters.

Many checks can be carried out using vision systems, but in many cases direct mechanical measurement is required — for example, to verify dimensions, clearances, applied forces or functional responses.

This is why we design complete control machines, able to adapt to the production flow and guarantee operational continuity, stable quality and zero waste.

Data traceability is guaranteed and direct communication with the MES system allows continuous, punctual and tailor-made control along the entire line.

Key points:

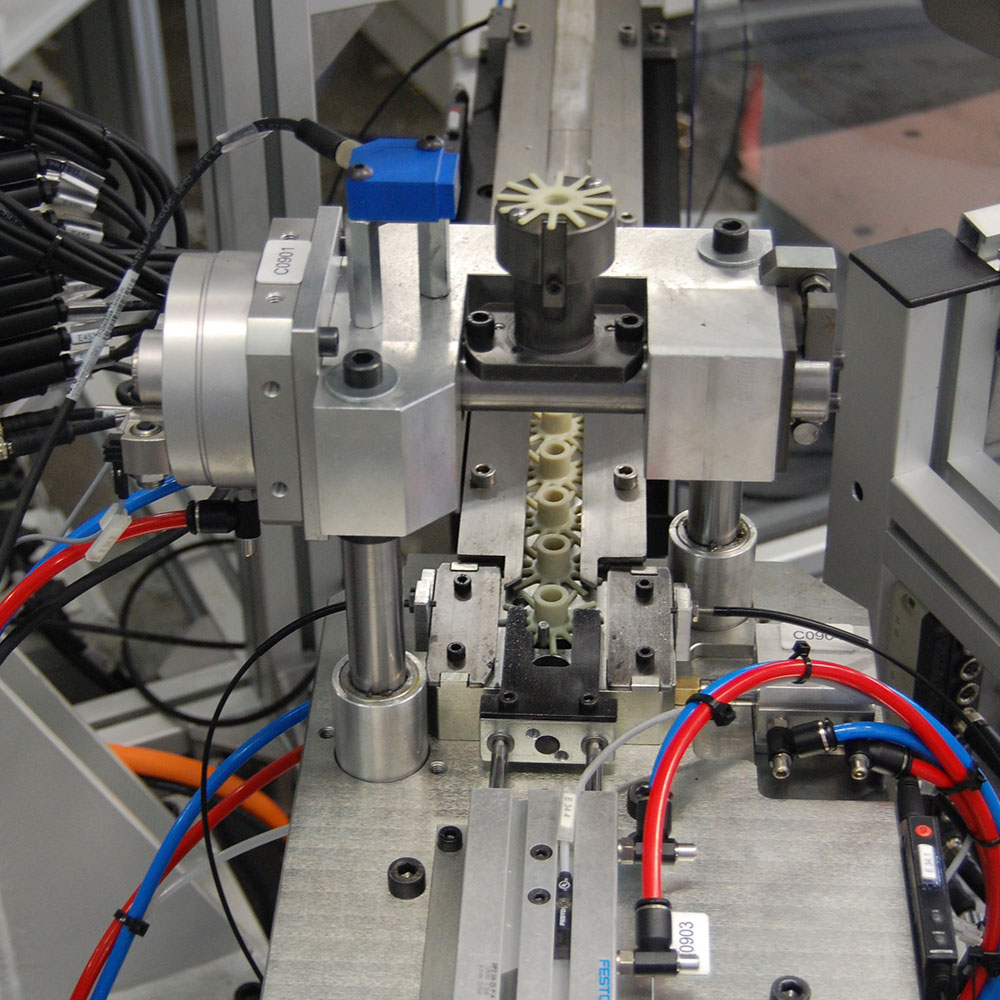

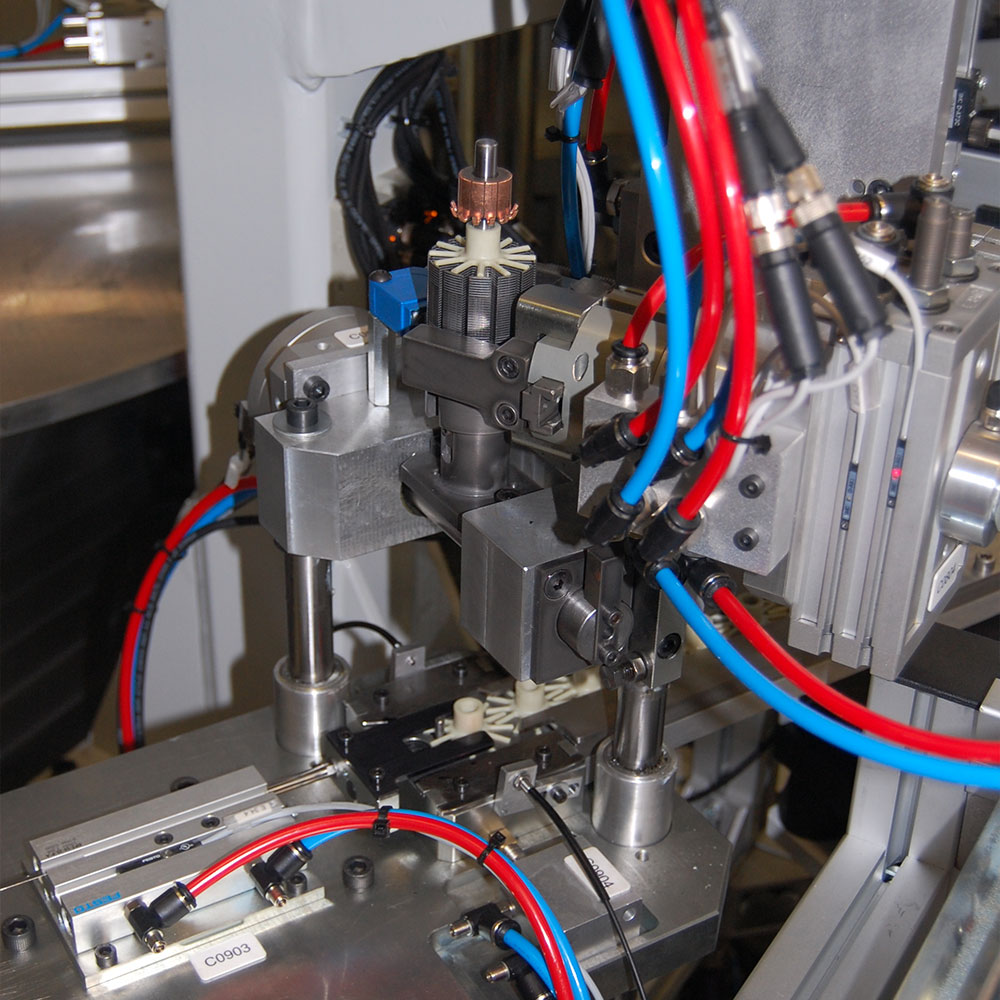

Flow, precision, scalability.

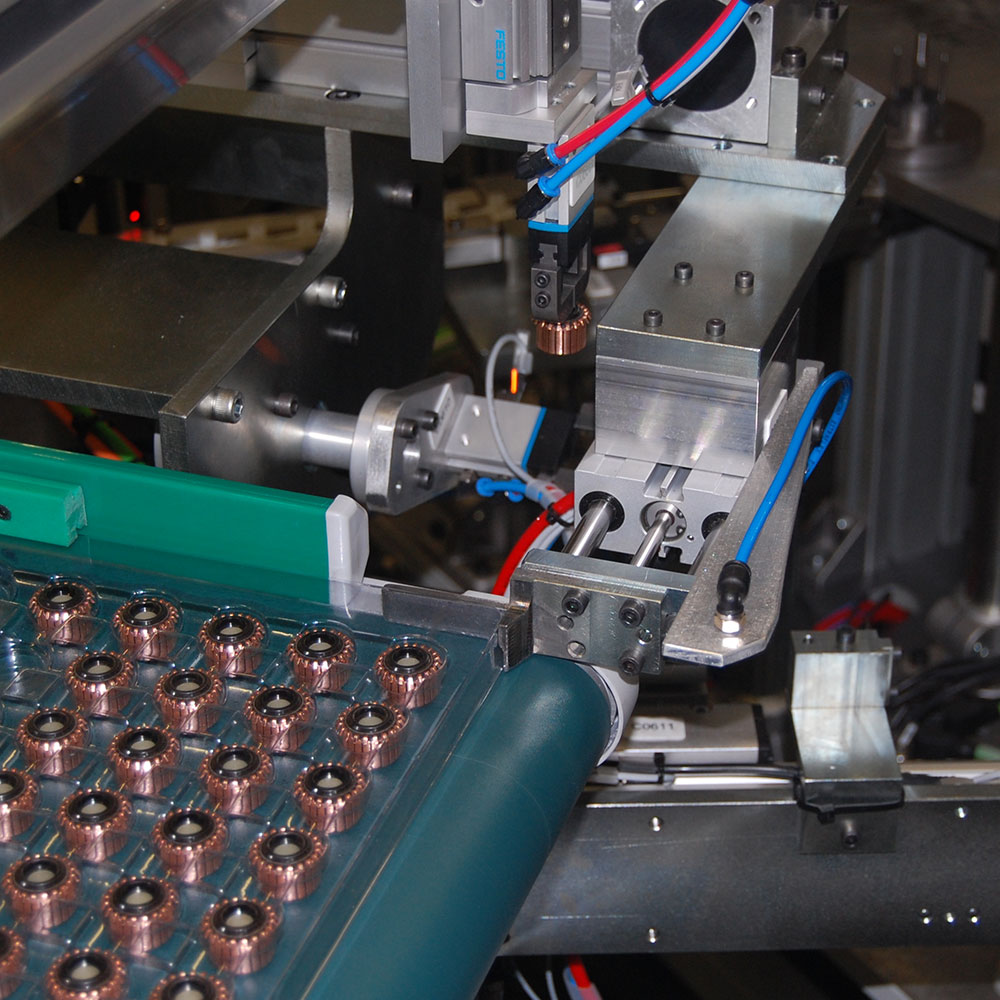

We automate assembly operations to increase repeatability, speed, accuracy, and process stability.

We design stations capable of performing critical, repetitive and cyclical operations in a coordinated, sequential and/or simultaneous manner, minimizing human intervention and optimizing line efficiency.

Each machine is configured according to the type of product, the expected volumes and the complexity of the tasks to be automated.

Key points:

Integration, traceability, continuity

Optimising the packaging process means much more than automating one of the production processes. It means bringing order, precision and punctuality to a crucial phase that connects production and logistics.

A well-designed packaging system not only protects the product, but integrates seamlessly with internal systems, communicates with logistics and ensures that each piece is tracked and ready to be stored or shipped in the most efficient way possible.

Choosing a solution that takes into account the needs of advanced traceability, intelligent end-of-line management and scalability is now a strategic advantage: it reduces errors, speeds up times and enhances the product from the first impact.

Key points: