Dema production lines are state-of-the-art customized automation solutions both from a mechanical and software point of view.

We design, manufacture, test and install winning machines with the highest standards of quality and precision, ensuring the traceability of the rotor or stator pack.

We listen to you, frame your production objectives and accompany you towards the winning solution thanks to production processes designed from time to time for your needs.

We deploy all our technologies to meet every special request.

Dema’s specialization is the automation of the processes necessary to produce stator and rotor packs. We follow in detail every step between blanking and winding to offer the best automated solution for the customer’s needs.

Each machine is developed and customized to ensure maximum productivity from the start.

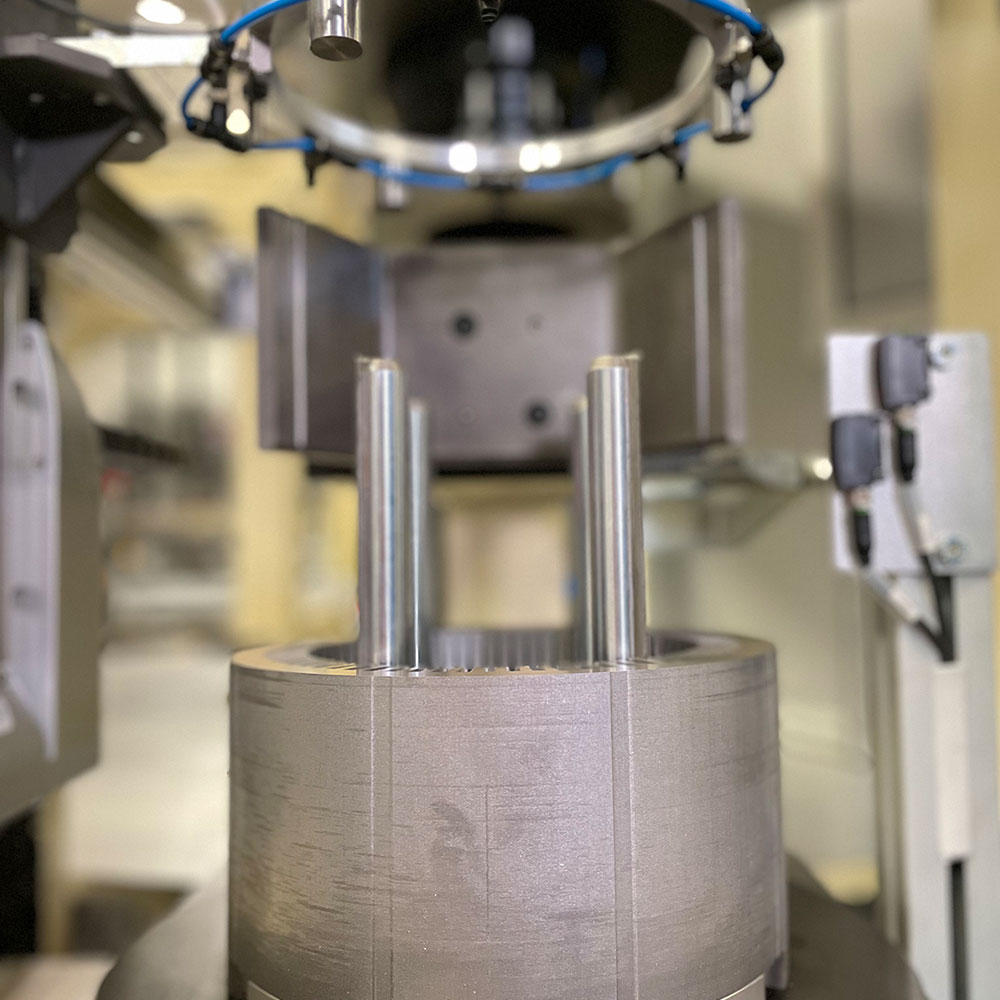

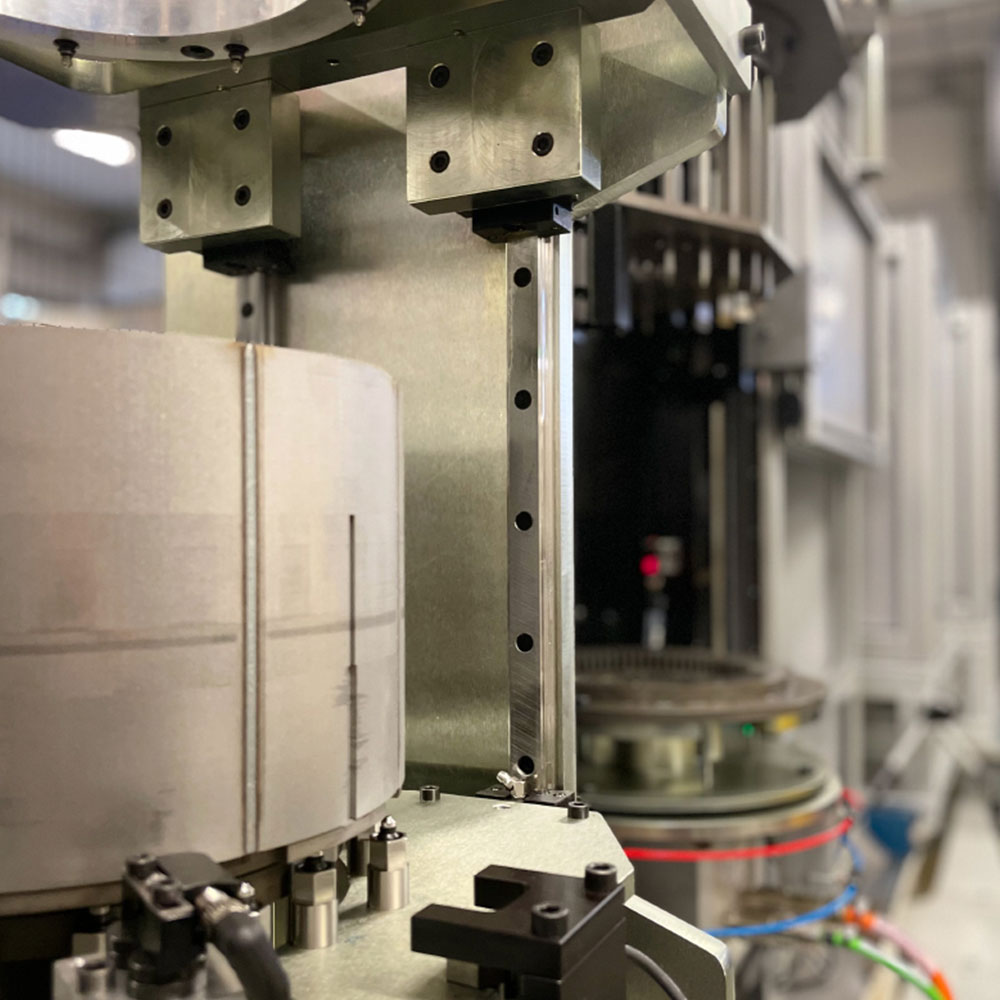

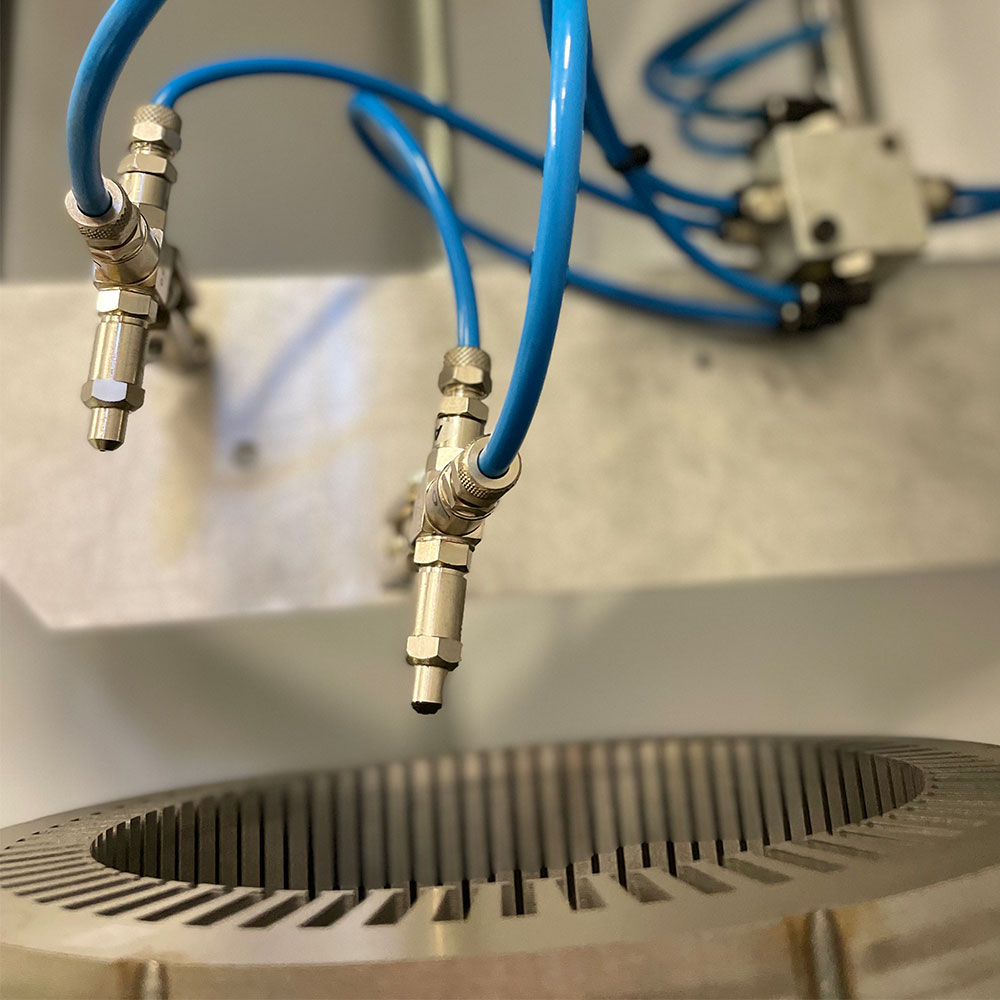

Stacking is packing, i.e. the process of sorting loose laminations and forming the rotor or stator pack.

The process allows you to select portions of loose sheets from vertical storage; these portions are compensated and assembled to make the stator or rotor pack. Dema machines, thanks to the technologies developed, are able to process any type of sheet metal.

E-powertrain

Innovative applications for the production of electric traction motors use our patented Salag technology.

New challenges

Thanks to our tailor-made approach, we set no limits and are ready to work even with even more challenging characteristics.

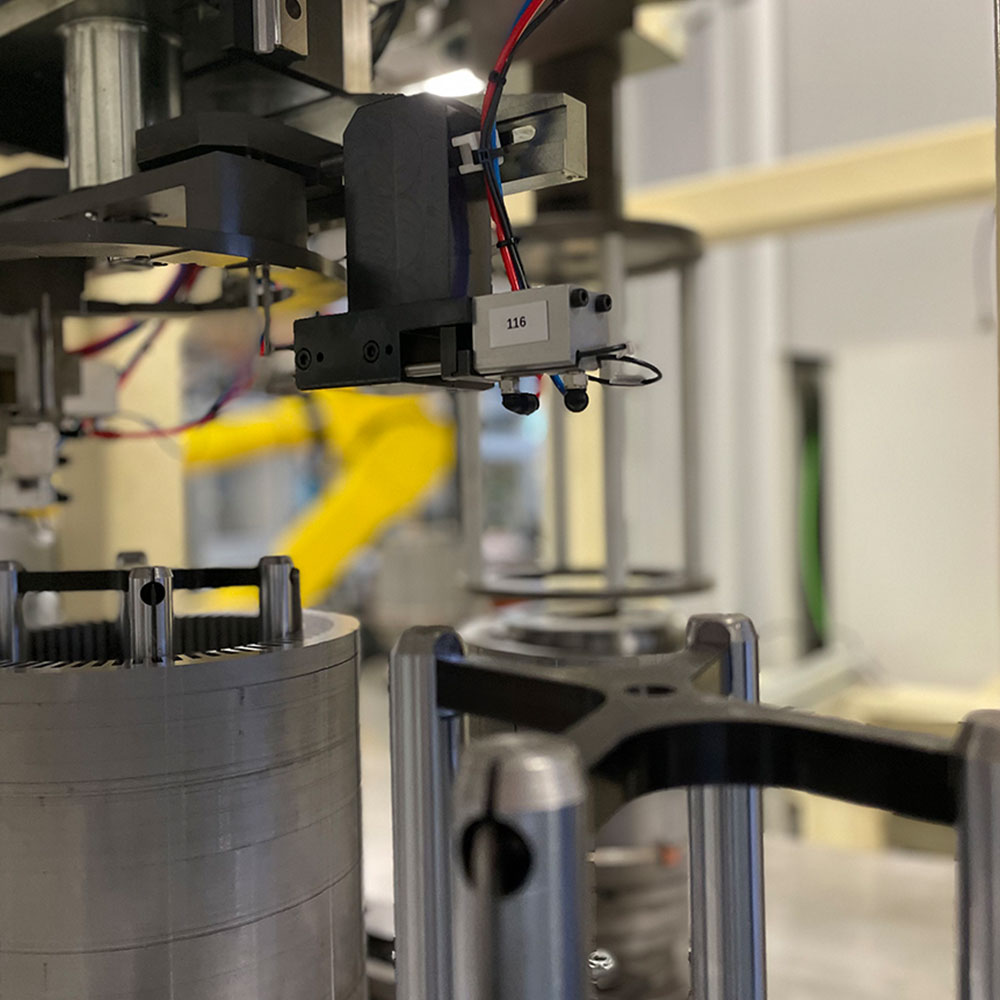

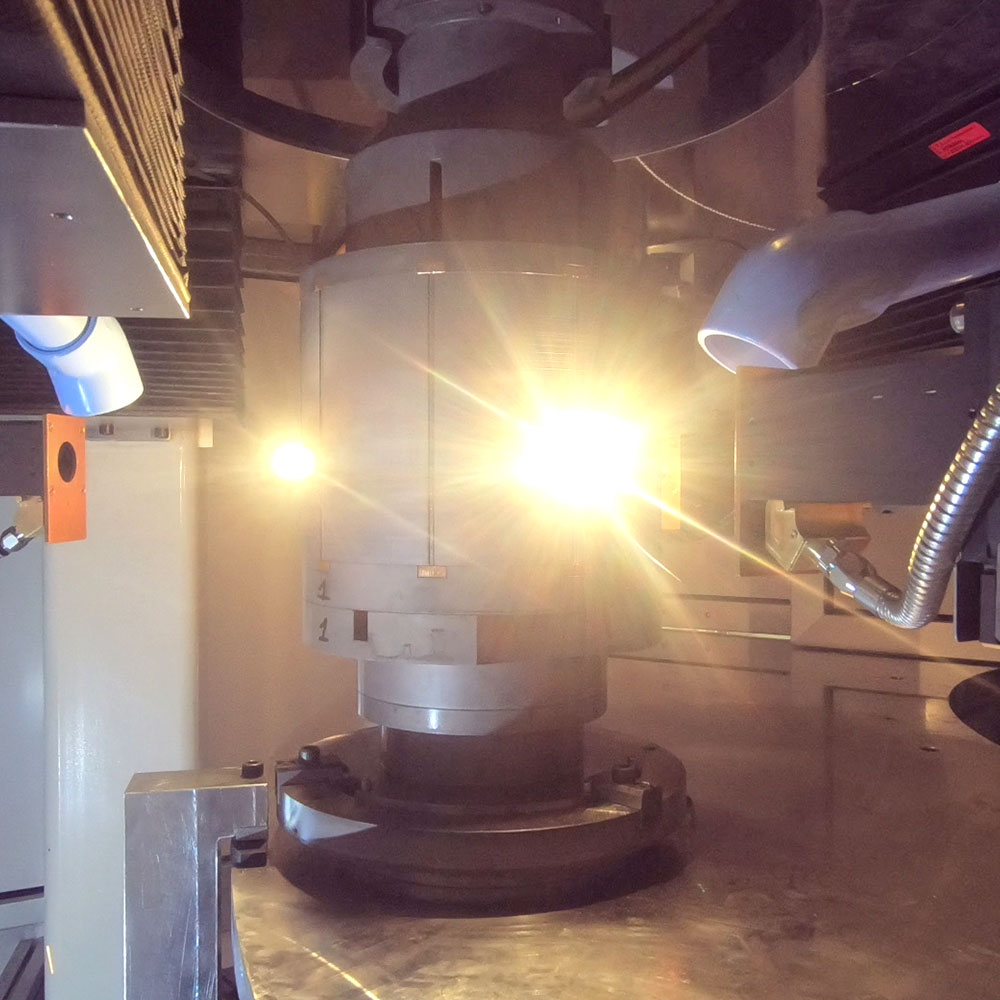

Joining refers to the competence of joining the laminations and holding them together to form the stator or rotor pack.

Our machines can carry out the defined process for the production of packs and Dema can provide its advice to define the most suitable process for each application. The most frequently used processes are laser, plasma, TIG or MIG welding and bonding with Backlack or Quick Self Bonding laminations.

DDLock

The most innovative method, which allows us to combine the advantages of welding and bonding technologies, consists in the hybrid solution developed and patented by us: Dema Double Lock

Stacking factor

The correct “stacking factor” in the pressure packs is determined and guaranteed by the repressing performed by our machines in the case of interlocked packs in the blanking die.

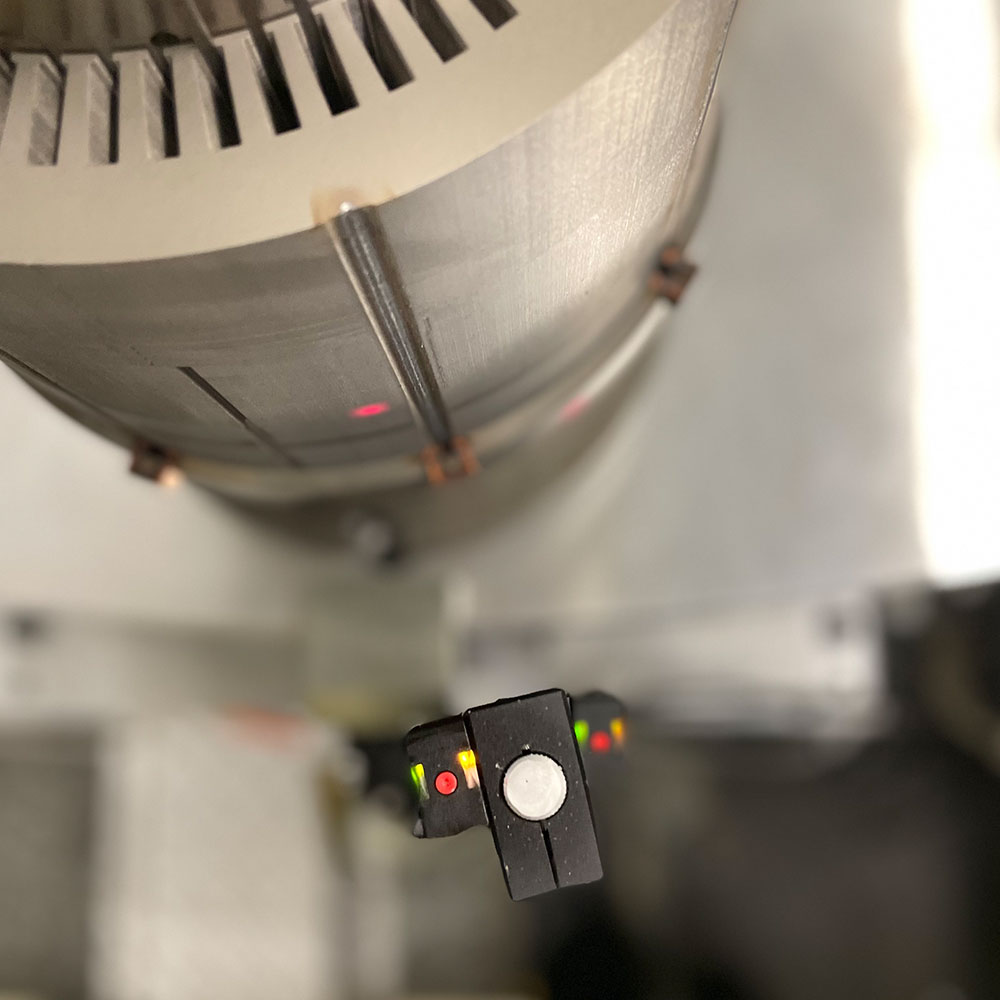

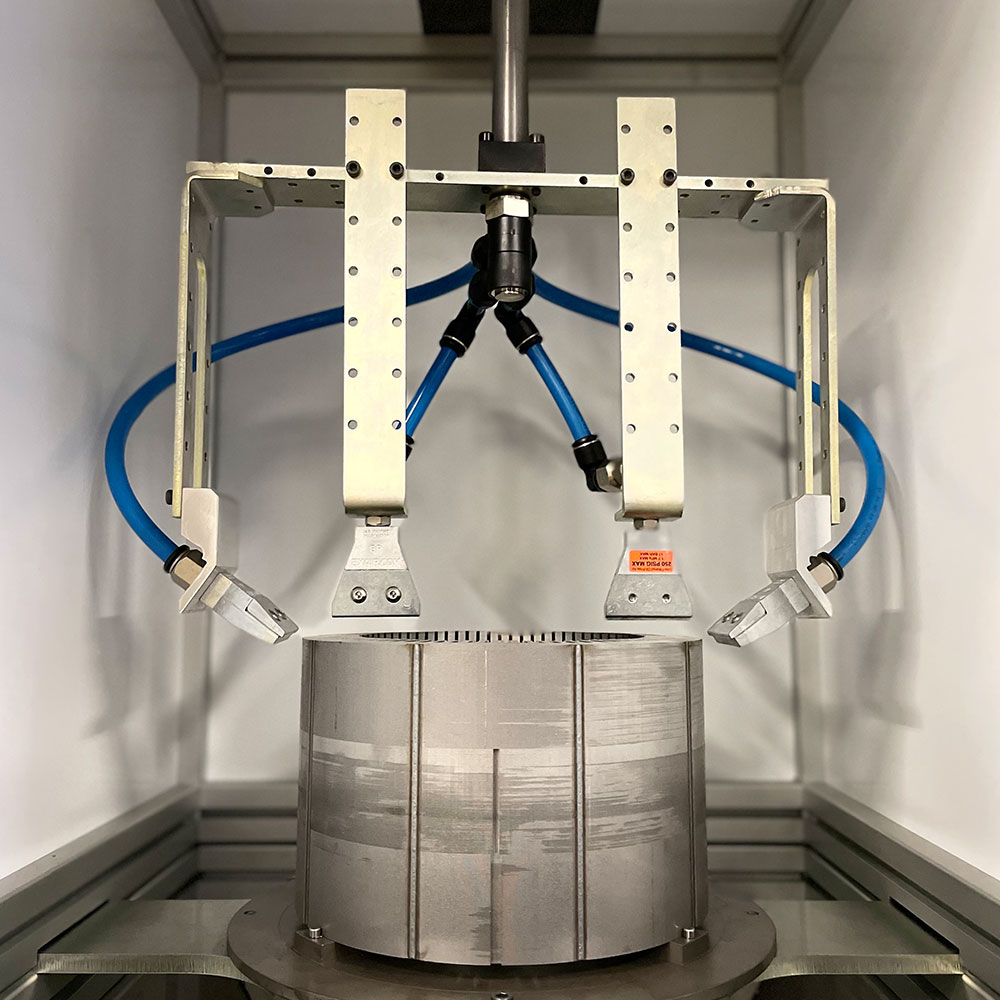

We develop control machinery for rotor and stator packs in the field of electric motors.

Our machines, using mechanical, laser or vision devices, perform checks to verify dimensional or shape tolerances and to evaluate further characteristics of the packages.

Knowledge of the package formation process has allowed Dema to develop effective and repeatable control solutions, which take into account the “non-homogeneous” nature of the objects to be inspected.

In order to avoid inconveniences in the subsequent production phases and to ensure the best performance of the electric motors, it is necessary that some characteristics of the stator and rotor packs are 100% in-line.

We provide special and customized automated solutions to respect the characteristics of each electric motor through specific combinations of visual and mechanical controls along the series process.

Additional operations may be required to complete the production process of stator packs and rotor packs.

Our machines allow you to perform the operations you need and our experience allows you to carry them out in the best possible way. Do I need to do more work on the stator and rotor packs? Need to automate any of the following processes?

Carving trees

We can carve trees directly during the process with numerous technical and economic advantages. During production, you will have full control over the frictional force when pressing the shaft to complete the rotor pack.

Inserting magnets

Dema machines are able to insert magnets (already magnetized or to be magnetized later) of various shapes and sizes. Fixing can be done through glue or through mechanical deformations.

DEMA has gained its experience working all over the world with leading companies in the automotive, household appliances, power tools and industrial sectors.

We know in detail the different and specific needs in different areas, which is why we are able to accompany you towards your goals with our technologies tailored to your needs.

It includes electric power train (engine) and accessory devices (seats, windows, windows, etc.).

This is the sector for which most quality controls are carried out and product traceability is often necessary.

It encompasses the world of household appliances that require large production volumes and require machines capable of working at speed while maintaining efficiency and precision.

Pumps, industrial engines and wind generators.

A sector that requires specific inspection processes working on large production volumes.